- UBS

- 1-5/8" Metal Framing

- 1-1/4" Metal Framing

- Unistrut 13/16" Metal Framing

- Pipe Clamps & Conduit Supports

- Fiberglass Unistrut System

- Food Grade Strut

- Sikla Heavy Duty Metal Framing

- Lindapter Structural Fasteners

- Telespar Mechanical Tubing

- Safety Grating

- Threaded Rod & Couplers

- Unistrut Hardware & Fasteners

- Concrete Anchors

- Dakota Systems Smart Products

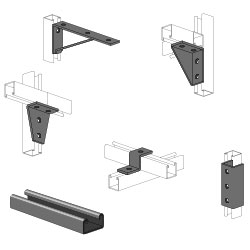

Unistrut Fabrication: UNIFAB

A Century of Custom Fabrication Expertise

Unistrut Buffalo proudly presents UNIFAB, leveraging a century of custom fabrication expertise as a division of Eberl Iron Works, Inc. (EIW). With a rich history dating back to 1923, EIW has been at the forefront of custom fabrication, specializing in bent plate forms, channels, and design-engineered solutions for the building and construction industries.

What sets UNIFAB apart is our direct access to a full line of state-of-the-art CNC machinery and equipment, coupled with the skills and experience to utilize it to its fullest potential. Unlike other Unistrut suppliers, our customized solutions are entirely designed, engineered, manufactured, and shipped in-house. This integrated approach not only ensures unparalleled quality control but also delivers significant time and cost savings for our clients.

By eliminating the need to outsource manufacturing steps, we streamline the production process, significantly shortening lead times and expediting product delivery. Our clients benefit from faster turnaround times without compromising on quality or precision. With UNIFAB, you can trust that your custom fabrication needs will be met with the utmost efficiency and professionalism.

At Eberl Iron Works, we employ CNC equipment to maintain tight material tolerances and achieve a high level of accuracy in every finished product. Whether it's precision cutting, bending, or forming, our CNC capabilities enable us to meet the most exacting specifications, ensuring that your custom fabricated components are tailored to your precise requirements.

With UNIFAB, you can rely on a trusted partner with a proven track record of delivering superior custom fabrication solutions. From concept to completion, our team is dedicated to exceeding your expectations and providing you with unmatched value, quality, and service. Experience the difference of UNIFAB for your next custom fabrication project.

Unistrut Fabrication Services

- Plasma Cutting

- Metal Shearing

- Metal Forming

- Turret Hole Punching

- Band Saw Cutting

- MIG Welding

- Cobot Welding

- Stud Welding

- Primer Coat Painting

- Powder Coating

- Hot Dip Galvanizing

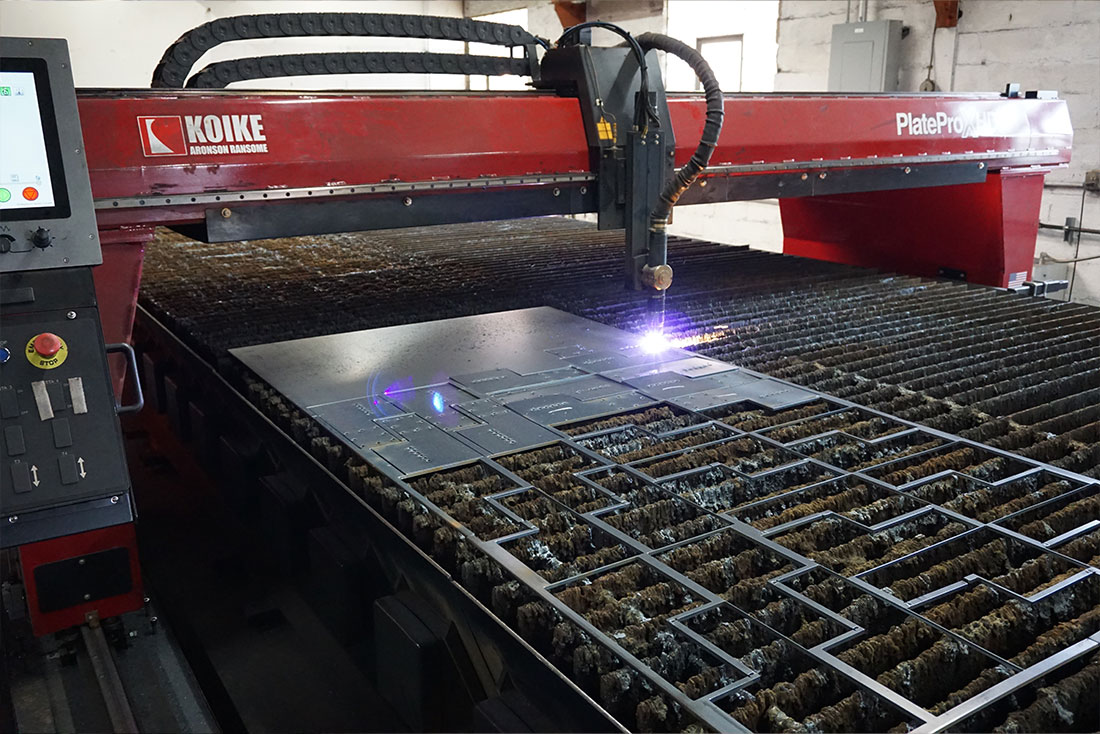

Plasma Cutting

Our Koike Aronson PlateProX HD 3100 machine was purchased in 2020 and the sparks have been flying ever since! With a 10 foot by 24 foot table and plasma cutting capabilities that extend to 1-3/4″ material thickness, there’s almost nothing we can’t do.

The PlateProX HD utilizes the latest technologies to provide unmatched speed, accuracy, versatility and durability in a CNC cutting system. Designed to satisfy the world’s most demanding customer requirements, the PlateProX HD has been engineered to maximize its’ performance while costing so little.

Plasma Cutting Capabilities

- Up to 1-3/4″ Material Thickness

- Up to 10 Foot Material Width

- Up to 24 Foot Material Length

Metal Shearing

The Eberl Iron Works manufacturing warehouse, located in Buffalo, NY since 1923, is home to our Cincinnati 500 Metal Shear, affectionately named, “Rita”. Rita can shear half inch thick metal plate that is up to twelve feet in length. Our sheet metal shear is also equipped with a conveyor and auto scrap separator for faster, cleaner metal shearing.

Metal Shearing Capabilities:

1/2″ Thick Material up to 12 Feet Long

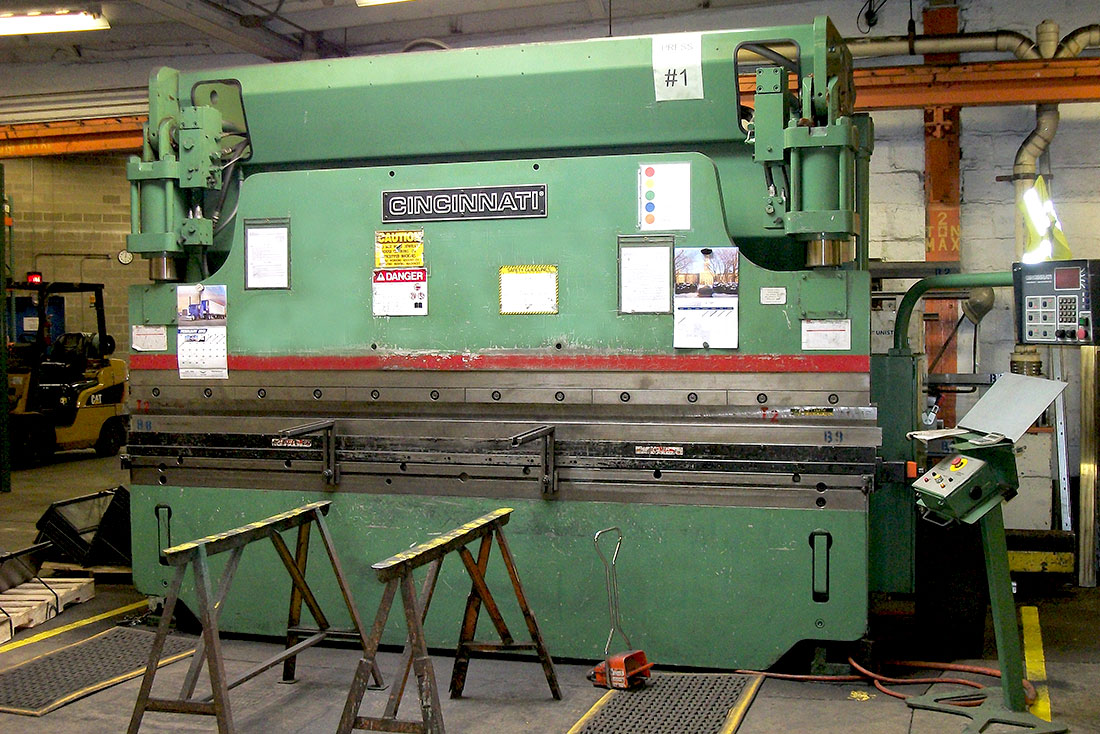

Metal Forming

EIW, is home to four Press Brake machines. Our largest machine is a Cincinnati 400 Ton Mechanical Press Brake which can bend 12 foot lengths of 3/8″ thick material and 6 foot lengths of 1/2″ material.

Bent Plate is one of our specialties – it would have to be after almost 90 years of bending steel! We offer a number of standard shapes to choose from, but we are also very comfortable working with you on your custom designs and projects. We’re always happy to take a look at customer drawings and come up with a fast and accurate quote for fabrication of your custom project.

Metal Bendring Capabilities:

- 3/8″ Material up to 12 Feet Long

- 1/2″ Material up to 6 Feet Long

Turret Punch Hole Punching

We offer state of the Art CNC Turret Punch Pressing services on site with our LVD STRIPPIT Parma 1212 CNC Turret Punch Press, to speed up production times and provide faster order turnaround. Our punch press offers fast, reliable, cost-efficient CNC punching. Hydraulic ram technology delivers the highest punching rates of any punch press in its class. The ram system, rugged frame and CNC control ensure tight tolerances and consistent punching accuracy.

The STRIPPIT features quick changes die holders for efficient setup and quicker job completion times. Our punch press die set can accommodate a large array of punched metal shapes and patterns, including:

- Round Holes

- Square Holes

- Rectangular Slotted Holes

- Oblong Slotted Holes, and more

Metal Band Saw Cutting

Our manufacturing facility is home to a number of metal band saws, including a Cosen 500 and Hydmech S20P, allowing us to offer cutting and deburring services for a wide variety of metal products. Our main saw station is equipped with a 20 foot gravity roller conveyor table support material and to make saw cutting of long lengths of tubing, grating, and channel easier and more accurate.

Our mechanized deburring machine insures that jagged metal edges are smoothed out and made safer for handling.

MIG Welding

EIW retains a number of highly skilled welders on staff. Our senior welder has been welding with us for more than two decades and brings invaluable knowledge and experience to our team.

Our staff includes fully certified welders who specialize in MIG welding operations. Although our welding department is not limited to MIG welding alone, we generally prefer it because it increases speed and job efficiency, allowing us to turn your order around that much more quickly.

Additionally, MIG welding is a very versatile form of welding and can be used to successfully weld every thickness of metal. It creates a strong, lasting bond on everything from fine, 26 gauge sheets to thick structural plates.

- Carbon Steel

- Stainless Steel

- Aluminum

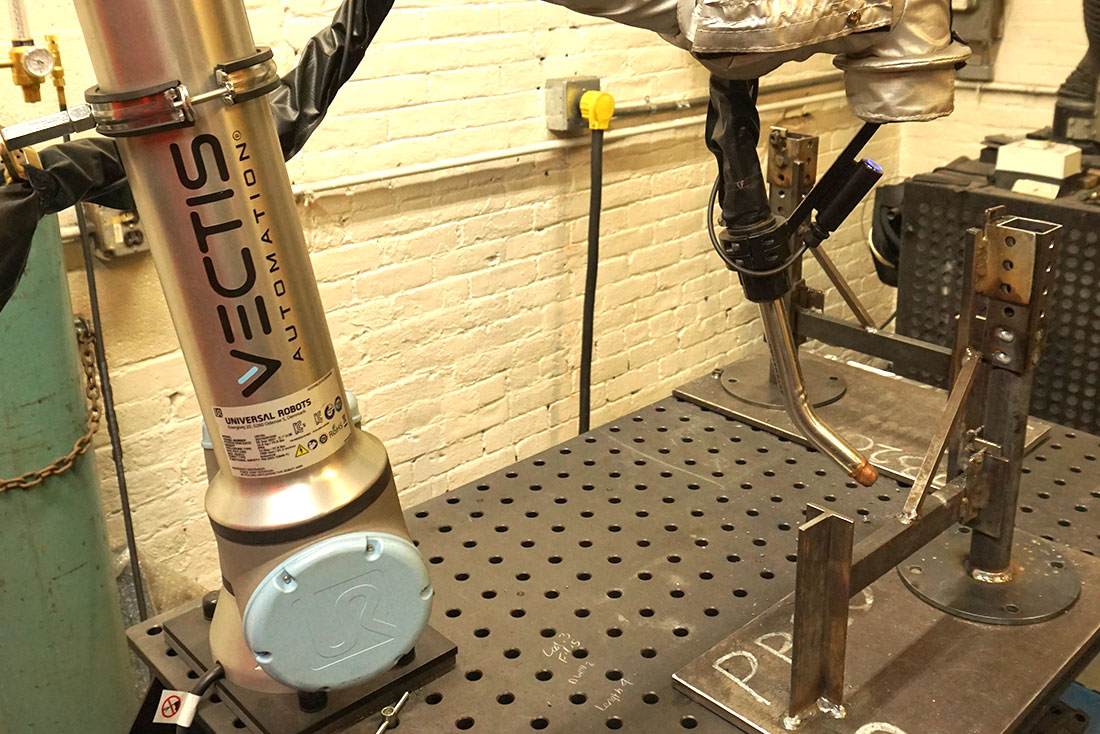

COBOT Welding

We've added Cobot Welding to our ever-expanding list of service offerings. With the recent purchase of our Vectis Standard-Duty, Air Cooled Welding Cobot we have the ability to turn out clean, accurate, consistent, high quality welded parts faster than ever before. Employing welding robots allows us to boost our productivity, by increasing the efficiency of repetitive welding jobs, and ultimately lower costs to our customers.

Automating welding production with the use of a robotic welder has also helped us speed up production to shorten our lead times even further. We are now able to complete the same job as much as four times faster and get parts out the door, and to where they’re needed, in much less time. Faster production equals shortened lead times!

Stud Welding

Our Nelson Nelweld Model 6000 Stud Welder was purchased in early 2023 and the sparks have been flying ever since! With a dual gun system configuration, we are able to securely fasten studs to metal in a fast, clean, and consistent process that lends itself perfectly to assembly-line style manufacture of embed plates, weld plates and more! Dual NS 20 N HD stud welding guns are able to be operated concurrently, which means we can knock your project out in a fraction of the time that it would take with more traditional welding techniques.

Material Coatings

- Primer Coat Painting

- Hot Dip Galvanizing

- Powder Coating

We offer primer coating services for our ferrous metal products, using red oxide paint, as well as other paints, depending on your application. Red oxide primer is a specially formulated for use as a base coat for ferrous metals, or metals that contain iron, to inhibit the formation of rust. Red oxide primer coat gives steel surfaces a layer of protection and also prepares their surface to receive a top coat. It is both weldable and paintable.

Hot Dip Galvanizing forms a protective coating that prevents moisture from making contact with the steel. This protects the metal from corrosion and rust.In addition to hot dipped pieces being both rust and abrasion resistant, they also require no maintenance. Once dipped, steel parts and channels should remain rust free for life, making them perfect for high moisture and/or outdoor applications.

Powder coating metal surfaces provides more resistance to chipping, scratching, and other wear than painting does. This is because the powder coat is thermally bonded to the metal during the curing (or baking) process. Powder coatings can also be applied in much thicker layers than paint can, which provides even more protection.

Fabrication Equipment

Coating Services