- UBS

- 1-5/8" Metal Framing

- 1-1/4" Metal Framing

- Unistrut 13/16" Metal Framing

- Pipe Clamps & Conduit Supports

- Fiberglass Unistrut System

- Food Grade Strut

- Sikla Heavy Duty Metal Framing

- Lindapter Structural Fasteners

- Telespar Mechanical Tubing

- Safety Grating

- Threaded Rod & Couplers

- Unistrut Hardware & Fasteners

- Concrete Anchors

- Dakota Systems Smart Products

Stainless Steel Unistrut

Get Better Performance with Unistrut Stainless Steel

The introduction of stainless steel Unistrut has been a game-changer in the industry. Composed of an alloy containing chromium, which forms a protective oxide layer on its surface, stainless steel boasts remarkable resistance to rust. The chromium content, often combined with other elements like nickel and molybdenum, creates a passive film that acts as an armor against the formation of rust.

Is Stainless Steel Corrosion Resistant?

YES! Stainless Steel Unistrtut offers five times the amount of corrosion protection that hot dip galvanized steel does, making it the most corrosion resistant material that Unistrut offers. For applications that need to be able to weather the elements, there is no material that offers more corrosion resistance than stainless Unistrut. This versatile and rust-resistant material has proven to be a game-changer in various applications, offering unparalleled resilience in even the most unforgiving settings.

Unistrut offers stainless steel in several different grades.

Type 304 Stainless Steel

Stainless Steel, Type 304 (SS): ASTM A240, Type 304 or A276, Type 304

Type 316 Stainless Steel

Stainless Steel, Type 316 (ST): ASTM A240, Type 316 or A276, Type 316

Why Use Unistrut Stainless Steel?

- Best Corrosion Resistance

- Superior Longevity

- Can Be Welded

How to Prevent Galvanic Corrosion Between Aluminum and Stainless Steel?

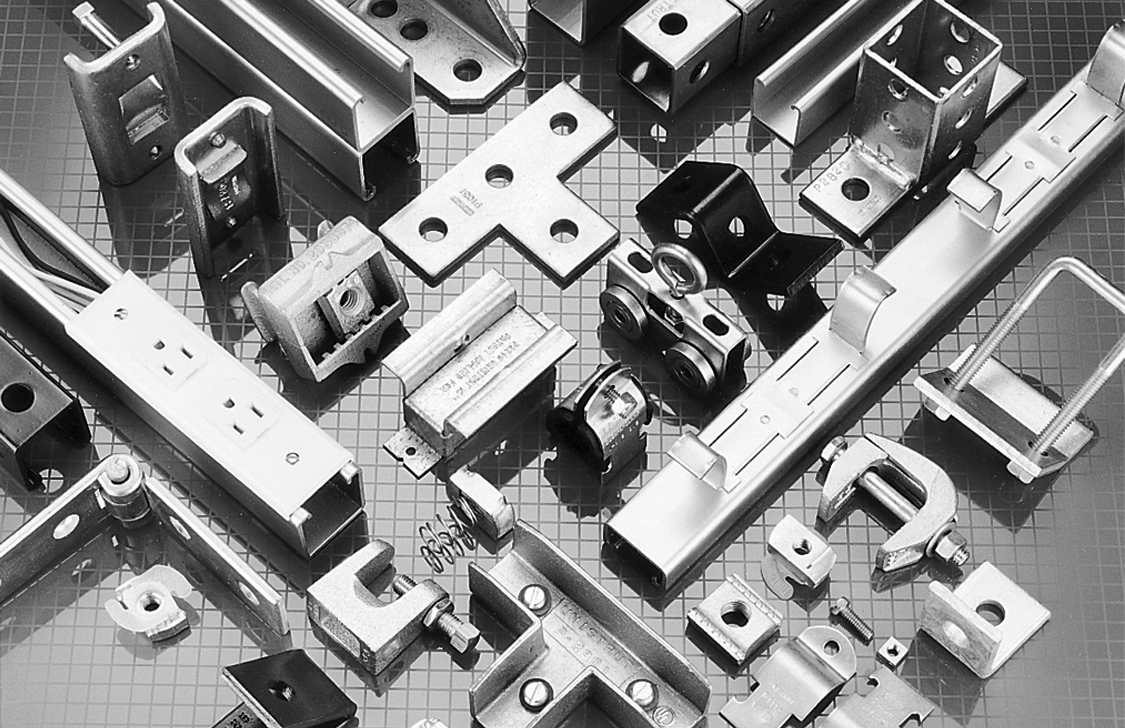

Within Unistrut's special metals category lies not only stainless steel st, but also aluminum. Most fittings and channels shown in the Unistrut catalog, are available in aluminum or stainless steel - though there may be a manufacturing lead time associated with some of the lesser sold items.

However, these two items should not necessary be used together.

Becuase they have a dissimilar galvanic potential, galvanic corrosion can occur when they come into contact with one another. Galvanic corrosion (aka bimetallic corrosion or dissimilar metal corrosion) is an electrochemical process in which one metal corrodes when it is in electrical contact with another, in the presence of an electrolyte.

The best way to avoid galvanic corrosion is not to pair these two metals together. But, if you do need to use them together, their are a few ways to curb galvanic corrosion:

- Applying coating or paint can act as a barrier

- The use of a gasket or other barrier layer between the two metals can inhibit corrosion

- Use of a third, sacrificial metal between them allows that metal to corrode first and preserve the other two metals

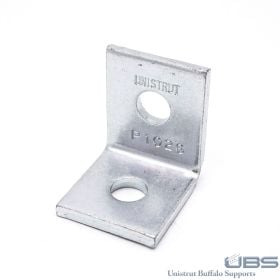

TOP SELLERS in STAINLESS UNISTRUT!

Sanitary, Clean Room & Pharmaceutical Applications

For applications on the food safety, pharmaceutical, or cleam room spectrum, we offer another stainless steel product that is manufactured, in the USA, specifically for those industries. Food Grade Strut has been designed for sanitary applications, so that it won't trap dirt, dust and debris, and can be more easily cleaned. Learn more about Food Grade Strut.

Technical Information

Material: STAINLESS STEEL

Channels: ASTM A 240 (Type 304)

Sintered Nuts: ASTM B783 (Type SS316N1-25)

Fittings: ASTM A240 (Type 304) or ASTM A276 (Type 304)

Type 316 stainless also available for most products.

Contact factory for specific material availability.

Column & Beam Load % Factor:

100%

Stainless Steel Applications

Stainless Steel is ideal for corrosive outdoor environments in many common applications including:

- Industrial Facilities

- Waste Water Treatment Plants

- Commercial Rooftop Supports

- Marine/High Salinity Environments

- Oil & Gas Processing Facilities

- Off Shore DrillingPlatforms

- Shipyards

- Refineries

- Power Plants

- Chemical Plants

- Breweries

- Railways

- Parking Structures

- Bridges

- Solar Panel Framing

- Walkways

- Platforms

- Railings

- Theme Parks

- and More!

Related Posts: Stainless Steel Unistrut