A Century of Expertise: Eberl Iron Works Legacy as a Premier Unistrut Supplier

In 1923, Eberl Iron Works, Inc. (EIW) was founded by brothers George and Frank Eberl in Buffalo, New York. The company initially focused on fabricating ornamental ironwork, such as decorative iron railings, gates, and other custom iron products. EIW quickly gained a reputation for high-quality craftsmanship, attention to detail, and exceptional service, which helped establish a solid customer base in the local community. This led to many growth opportunities for the company, one of which was the addition of the Unistrut Metal Framing line of products and expansion into new areas of building and construction as an independent Unistrut Distributor.

Eberl Iron Works

In the early 1940's Eberl Iron Works was invited to become a distributor of an innovative new metal framing product called Unistrut. During that same time period, EIW was also heavily involved in the manufacture of steel bumpers for Jeeps, in support of war efforts. The economic boom following World War II spurred major growth in construction and infrastructure projects. Eberl Iron Works capitalized on this by expanding its offerings and creating the Unistrut Buffalo Supports (UBS) division to complement what became the Metal Fabrication Services (MFS) division.

In the early 1940's Eberl Iron Works was invited to become a distributor of an innovative new metal framing product called Unistrut. During that same time period, EIW was also heavily involved in the manufacture of steel bumpers for Jeeps, in support of war efforts. The economic boom following World War II spurred major growth in construction and infrastructure projects. Eberl Iron Works capitalized on this by expanding its offerings and creating the Unistrut Buffalo Supports (UBS) division to complement what became the Metal Fabrication Services (MFS) division.

Around that time, the company also began to diversify into different types of metalwork, moving beyond ornamental iron to include more functional and structural components, such as stairpans, stair treads, and other custom bent steel fabricated products.

In 1967, Frank's sons Frank and George joined Eberl Iron Works, embracing modern manufacturing techniques, technological advancements, and company-wider modernization throughout the 1980's and 90's. Automated machinery and advanced fabrication processes were implemented. This shift allowed for increased precision, efficiency, and the ability to handle larger and more complex projects.

In 1967, Frank's sons Frank and George joined Eberl Iron Works, embracing modern manufacturing techniques, technological advancements, and company-wider modernization throughout the 1980's and 90's. Automated machinery and advanced fabrication processes were implemented. This shift allowed for increased precision, efficiency, and the ability to handle larger and more complex projects.

That legacy of innovation and expansion was continued when Frank's daughter, Nora, and George's son, John, took over as the Third Generation of Eberl Owners in 2012. Together, the cousins have further expanded EIW's offerings to include several more specialized divisions to better serve different market segments, including:

- Traffic Safety Products (TSP)

- Rooftop Support Systems (RTS)

- Stair Components & Systems (SCS)

- Modular Mechanical Supports (MMS)

Find out more About Eberl Iron Works

Genuine Unistrut Distribution Since the 1940s

The concept of Unistrut began in the early 1920s when Charles Attwood, an inventor and entrepreneur, sought to develop a more efficient system for building support structures. He recognized the need for a versatile and reusable framing system that could be easily assembled and adjusted without welding or other permanent methods. In 1924 he founded The Van Walraven Company in Wayne, Michigan, which later became known as Unistrut Corporation. The name "Unistrut" is derived from "universal strut," reflecting the product's intended versatility.

Attwood's innovative system was patented, and it quickly gained popularity due to its simplicity, strength, and flexibility. The Unistrut system could be used in a wide range of applications, including electrical and mechanical supports, pipe and conduit supports, and general framing. Its modular design and ease of installation made it an attractive alternative to traditional welded or riveted structures. During the 1930's and 40's, rapid adoption of Unistrut in various industries and expansion of the Unistrut product line gave way to the need for a nationwide network of Unistrut distributors. Enter Eberl Iron Works.

Eberl Iron Works has been a distributor of genuine Unistrut Metal Framing products since the 1940's and has the singular distinction of being The World's Longest Consecutively Running Independent Distributor of Unistrut Metal Framing. We were also the first Unistrut supplier to create a website dedicated to the sale of Unistrut products, where customers could add Unistrut channel, parts, and hardware to their cart and complete their purchase 100% online. We've been selling genuine Unistrut Framing products online since the early 2000's.

Unistrut's success in the United States led to its expansion into international markets. The company established manufacturing facilities and distribution networks in various countries, making Unistrut a global leader in metal framing systems. The Unistrut system became a standard in the construction and engineering industries, influencing the development of similar modular framing systems. Its impact is evident in the widespread use of channel framing systems in modern construction and industrial applications.

Unistrut Buffalo Supports: A Tradition of Customization

With a product as versatile as Unistrut, the possibilities for customizing solutions across industries, applications, and even into the DIY-sphere are almost limitless. Our UBS division has been at the forefront of customizing and implementing many of these systems since we began utilizing Unistrut framing over seven decades ago. In addition, Unistrut components play a key role in many of the modular systems we build in our Rooftop Support Systems and Modular Mechanical Supports divisions.

UBS: ceiling grids for medical equipment support, lighting, signage and other support applications, catwalks, mezzanines, storage racks, pipe & conduit supports, and much more.

UBS: ceiling grids for medical equipment support, lighting, signage and other support applications, catwalks, mezzanines, storage racks, pipe & conduit supports, and much more.- RTS: rooftop pipe and duct supports, access platforms, maintenance platforms, equipment supports, roof stairs, ramps, and much more.

- MMS: equipment skids, pipe racks, trapeze pipe supports, and much more.

- DIY: hunting blinds, garage storage, gym equipment supports, vehicle roof racks, engine hoists, and so much more...

Decades of Expertise in Metal Framing Solutions

Eberl Iron Works has spent over 70 years working with contractors, engineers, architects, and end users to design and engineer custom metal framing solutions to satisfy the unique needs of each and customer we've served. The combined knowledge, skills, and experience of our team members is hard to beat, and the level of customer service we provide is second to none. Our reputation for quality and innovation, tied with our dedication to providing top notch service has afforded us with opportunities to serve many different industries, from medical construction, mining, oil & gas refineries, pharmaceuticals, marine research, and original equipment manufacturers, to schools & universities, theaters, end users, and everyone in between.

Unistrut is truly a universal product that spans a diverse range of metal framing applications, and we are grateful to have had the opportunity to provide so many different types of customers with so many Unistrut metal framing products, services and solutions over the last seven plus decades.

UNIFAB: State-of-the-Art CNC Machinery and Equipment

UNIFAB, a combination of "Unistrut" and "fabrication" leverages over a century of custom fabrication expertise, specializing in bent plate forms, channels, and design-engineered solutions, with seventy plus years of expertise gained as a Unistrut supplier.

UNIFAB, a combination of "Unistrut" and "fabrication" leverages over a century of custom fabrication expertise, specializing in bent plate forms, channels, and design-engineered solutions, with seventy plus years of expertise gained as a Unistrut supplier.

What distinguishes UNIFAB is our direct access to a comprehensive range of cutting-edge CNC machinery and equipment, combined with the expertise to maximize its potential. Unlike other Unistrut suppliers, our custom solutions are entirely designed, engineered, manufactured, and shipped in-house. This integrated approach ensures exceptional quality control and offers significant time and cost savings for our clients.

By eliminating the need for outsourcing any manufacturing steps, we streamline the production process, greatly reducing lead times and speeding up product delivery. Our clients enjoy faster turnaround times without compromising on quality or precision. With UNIFAB, you can trust that your custom fabrication needs will be met with the highest efficiency and professionalism.

EIW uses CNC equipment to maintain tight material tolerances and achieve a high level of accuracy in every finished product. Whether it's precision cutting, bending, or forming, our CNC capabilities allow us to meet the most exacting specifications, ensuring that your custom fabricated components match your precise requirements.

With UNIFAB, you can depend on a trusted partner with a proven record of delivering superior custom fabrication solutions. From concept to completion, our team is dedicated to exceeding your expectations and providing unmatched value, quality, and service. Experience the UNIFAB difference for your next custom fabrication project.

Want to Know More About our Capabilities?

Visit our UNIFAB page

for a comprehensive listing of our most sought-after services

Looking for a "Unistrut Supplier Near Me"?

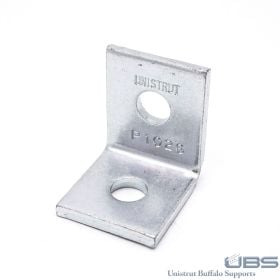

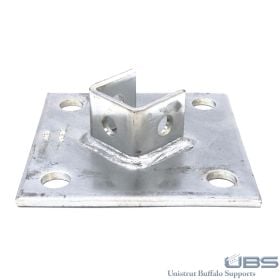

Look no further, we are one of the largest stocking distributors of genuine Unistrut Channel, Unistrut Fittings, Unistrut Hardware, and Unistrut Accessories in the U.S. with nationwide shipping and quick order turn around. There no need to scour the internet for "Unistrut distributors near me" - we've been expanding operations, and committing to stocking a wider array or products in larger quantities over the last few years. We also utilize a network of support partners for rare times when we don't have exactly what you need, leveraging our drop ship capabilities to ensure that you have what you need when you need it.

So head on over to our product catalog and start filling your cart with Genuine Unistrut Metal Framing right now!