- UBS

- 1-5/8" Metal Framing

- 1-1/4" Metal Framing

- Unistrut 13/16" Metal Framing

- Pipe Clamps & Conduit Supports

- Fiberglass Unistrut System

- Food Grade Strut

- Sikla Heavy Duty Metal Framing

- Lindapter Structural Fasteners

- Telespar Mechanical Tubing

- Safety Grating

- Threaded Rod & Couplers

- Unistrut Hardware & Fasteners

- Concrete Anchors

- Dakota Systems Smart Products

Unistrut Channel: Selecting the Right Strut for Your Application

Selecting the Right Unistrut Channel for Your Application

Choosing the right Unistrut channel for your job doesn't have to be a chore

When selecting Unistrut Channel for your project, there are a few things you'll want to consider in order to make sure you're getting the correct one for your application. Below we'll let you know exactly what to think about and then break it all down for you, in further detail.

Things to Consider When Purchasing Unistrut Channel

- Profile Dimensions - Are there size requirements/limits where you are installing?

- Solid or Holes - How are you planning to mount your channel? Bolt through? Suspended by rods? With fittings?

- Finish - Do you need to weld it? Is it going out doors, or in a corrosive environment?

- Loading - How much weight does it need to hold?

- Combinations - Does your application require a different configuration than one, single channel?

Profile Dimensions (Width and Height)

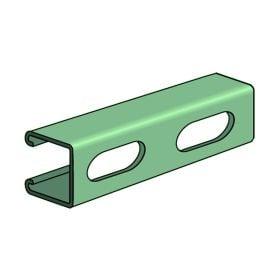

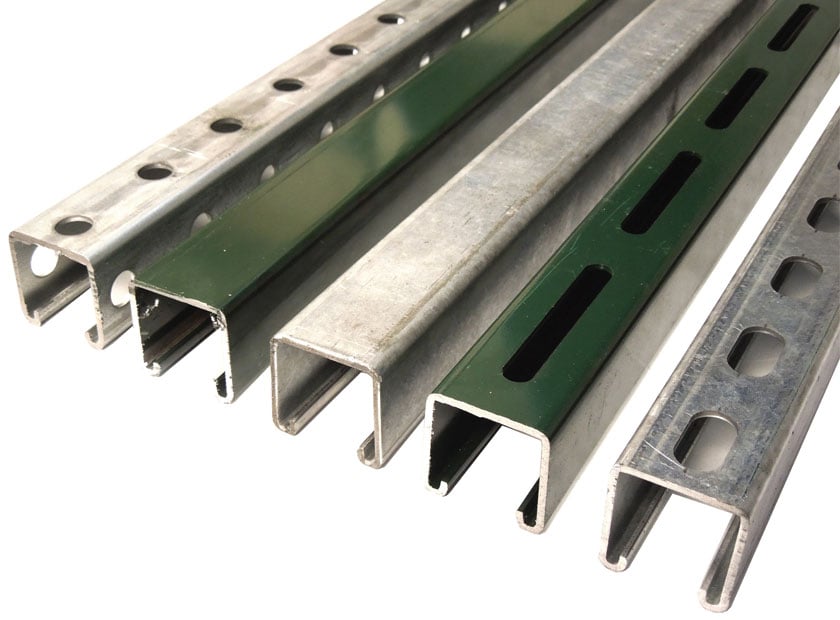

Unistrut P1000, which has an 1-5/8" x 1-5/8" profile, is by far our most popular channel. The factory produces it in much higher volumes and it is more readily available. Therefore, it is typically the most cost effective and the most widely stocked. The parts and fittings that are manufactured for the 1-5/8" series are also more readily available. So if you've got a job that you're ready to move on right now, Unistrut P1000 is usually your safest bet.

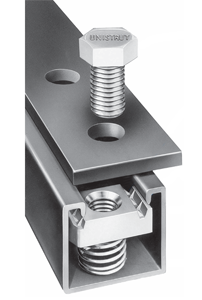

The Unistrut P1000 channel, and all other Unistrut framing members, are cold-formed from low carbon strip steel, with a continuous slot along one side, and inturned edges, forming an open 'c' shape. Inturned channel edges work in conjunction with the channel hardware (channel nuts, spring nuts, stud nuts, qwik washers, etc.) which have textured grooves, to create a more secure connection point.

Unistrut P1000 channel - the accepted standard for use in mechanical, electrical and general construction - is designed for heavy duty applications and made out of sturdy,12 gauge material.

However, within the 1-5/8" wide series of channel, there are also a number of other channel profile heights to consider - and even several other 1-5/8" x 1-5/8" strut profiles made of a lighter gauge materials (P2000 14 ga & P1100 16 ga).

1-5/8" Wide Unistrut Channels:

- P1000: 1-5/8" Height ** Most Popular Channel

- P1100: 1-5/8" Height (less common, not heavily stocked)

- P2000: 1-5/8" Height (less common, not heavily stocked)

- P3000: 1-3/8" Height (less common, not heavily stocked)

- P3300: 7/8" Height ** Most Popular Shallow Profile Channel

- P4000: 13/16" Height (Shallow Channel)

- P4100: 13/16" Height ** Most Popular 13/16", Shallow Profile Channel

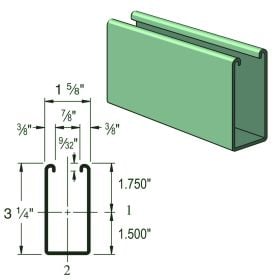

- P5000: 3-1/4" Height (Deep Channel)

- P5500: 2-716" Height (Deep Channel)

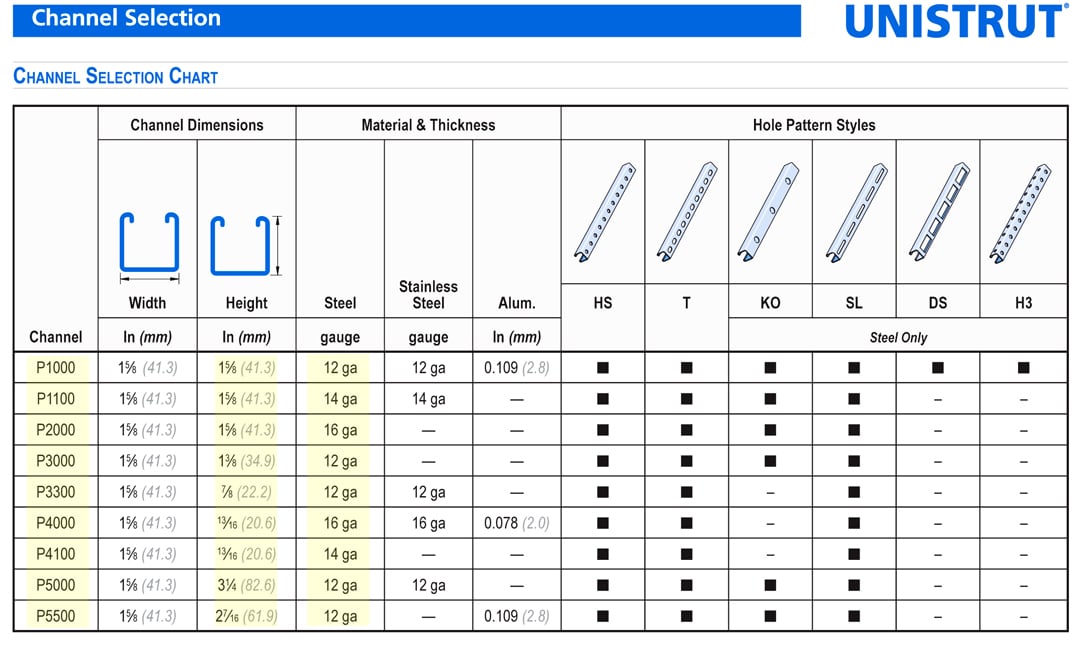

Check out the handy chart below for a list of 1-5/8" wide channel, with channel height (also referred to as channel depth), channel gauge and available hole patterns

Aside from Unistrut's 1-5/8" series channel, there are also several, less common series of channel, made for medium to light duty applications.

The A series of channels is 1-1/4" wide, 14 ga. (A1000: 1-1/4" x 1-1/4", A3300: 1-1/4" x 3/4", A4000 (19 ga) 1-1/4 x 5/8". The A series Unistrut Channel is for medium duty applications and has its own line of fittings and hardware.

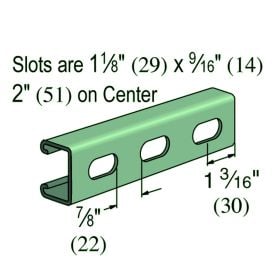

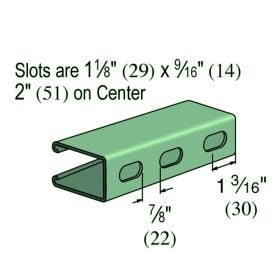

The P6000 & P7000 Series are 13/16" wide, 19 ga. P6000 is 13/16" x 13/16" and P7000, a shallow profile channel, is 13/16" x 13/32". These also have their own line of fittings and hardware and are meant for light duty applications.

Channel Length

The standard lengths for nearly all Unistrut channels are 10 feet, or 20 feet (though a few are available in 16 foot lengths). So, bear in mind that channel will need to be transported on a box truck or flat bed, unless you have small quantities cut to length for UPS shipping. Bundles of channel are typically 50 pieces, so a bundle of 10 foot lengths will contain 500 linear feet and a bundle of 20 foot lengths will contain twice as much material, 1000 linear feet.

Saw cuts are typically an additional charge, as they are an add-on service, and most distributors will charge you for a complete length (at least 10 feet), even if you only need two 24 inch pieces.

The reason for this is that they may have no use for the odd lengths, except for the scrap bin, and no way to inventory them in their system. You will almost always need to pay for a full, saleable length. (If you need twenty lengths that are 11 feet long, you'll be charged for twenty, 20 foot lengths and may as well ask for your 9 foot 'drops', in case you need them for another project).

For very large quantities of non-standard lengths of Unistrut Channel, you can request a special run of material, but there may be a lengthy lead time and you will need to get an estimate to ascertain whether it is a more cost effective option for you.

Solid or Holes?

It's important to consider what you're using your Unistrut channel for when deciding whether to go with a solid channel or one with holes or slots. Are you building something with it, like a shelf or rack? Are you mounting it to a wall, or suspending it from the ceiling? If so, how do you plan to do that? Do you need to bolt though the channel?

These are questions you should think about. If you are planning on bolting anything through the channel, you may want to consider a channel with holes or slots, so you do not have to drill through it - Unistrut channel is supposed to be easy to install, without the need for drilling or welding!

The 'T' slot style is by far our most common hole pattern. The back side of the 'T' slot channel has elongated slots which accommodate 1/2" hardware. (Refer to the diagram above to see which channels are offered in which hole different hole patterns). The elongated holes (or slots) of the 'T' style channel make it easier to adjust and secure than a round hole channel, where there's no room to make adjustments.

'HS' style channel has a row of round holes, which also accommodate 1/2" hardware (but don't allow for adjustment beyond choosing another hole to use).

'H3' is similar to 'HS', but the holes are located along all three sides of the channel. **Only available for P1000 channel

'SL' has elongated rectangular slots which accommodate 3/8" hardware.

Much less common are the 'KO' (or Knock Out round holes), and 'DS' ( wide, elongated rectangular slots **Only available for P1000 channel).

Something else to consider when choosing holes or solid strut is channel strength. 'SL' and 'T' slots channels have a reduction factor of 15% to solid channel, and 'HS' has a reduction factor of 10%, so there are slightly less strong and able to hold less weight.

Channel Finish/ Special Metals

Channel Finish/ Special Metals

Most Unistrut Channel is available in Plain Carbon Steel, Perma-Green, or Pre-Galvanized finish. Other options include hot-dipped galvanized and special metals (aluminum and Type 304 & 316 stainless steel). Though other finishes can be used to weld, plain carbon steel (no finish, black steel, bare steel), which has only a light coating of oil, to help prevent rust, is typically the preferred 'finish' for welding.

Carbon steel is no good for outdoor environments or environments with a lot of moisture or corrosive elements. Carbon steel will rust over time. It can however be hot dipped, powder coated or painted. So it might make sense if you are using it in the manufacture of something, which you plan to apply a finish to after production has been completed.

Perma-Green and Pre-Galvanized are the most common finishes and offer a decent amount of protection against humidity, weather and chemical/corrosive agents. Hot-dipped galvanized finish is similar to pre-galvanized, but has a thicker, more robust layer of galvanizing, while special metals, like aluminum and stainless steel, provide their own unique set of benefits. Refer to the Unistrut Catalog for technical data on product finishes and material specs.

Loading

As mentioned previously, having holes or slots in your channel lessens the amount of weight they can hold. The different gauges, along with the sizes and lengths of the various Unistrut channel profiles will determine how much weights each member can support. The Unistrut Catalog contains complete column and beam loading data charts for each type of channel manufactured by Unistrut. Refer to these charts, or contact a Unistrut Product Engineer, directly through the Unistrut website (be sure to select the 'Product Engineering' radio button at the base of the form).

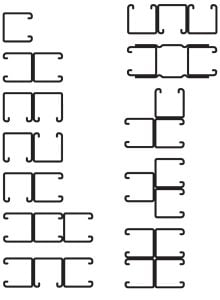

Combination Channels

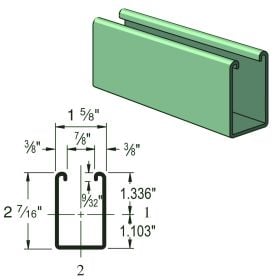

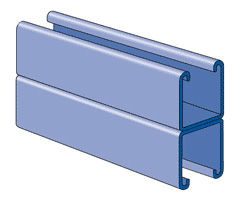

Now that you know just about everything there is to know about single lengths of Unistrut channel, let's talk about channel combinations. A channel combination simply means two or more pieces of channel that are welded together. The most common configuration is back-to-back. Unistrut P1001 is the most commonly sold back-to-back channel. It is two pieces of Unistrut P1000 welded together, for an overall dimension of 1-5/8" x 3-1/4".

Two channel combinations can also be made by welding side-to-side or side-to-back. There are also three and four channel combinations in a variety of

configurations. Consult the Unistrut Catalog to see what is manufactured.

It is advisable to check availability with your distributor and leave plenty of lead time when incorporating combinations into your design, since they are often not stocked (besides the most common ones, like P1001) and may need to go into production, specifically for your job. A 6-8 week lead time is not uncommon for channel and parts that need to be produced to meet demand.

Now that you know just about everything there is to know about Unistrut channel, be sure to scroll down to the bottom of this blog for Product Page links!

Product Pages include more detailed information about each specific product, including:

- Loading Tables

- Materials & Finish Specs

- Section Elements

- Product Drawings and Submittals (Downloads Tab)

- and more!

Once you navigate to the Product Page, just scroll down to the tabbed section below the product image and click the tab you want!