Unistrut Mounting: Top 3 Ways of Hanging Unistrut from Ceiling

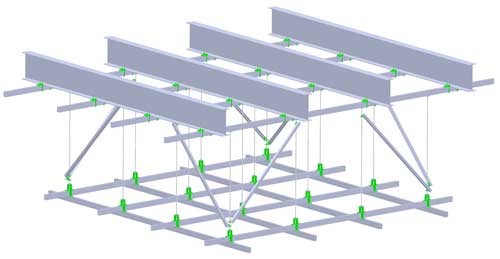

How to Use Unistrut Mounting Techniques When Installing Unistrut Ceiling Grids

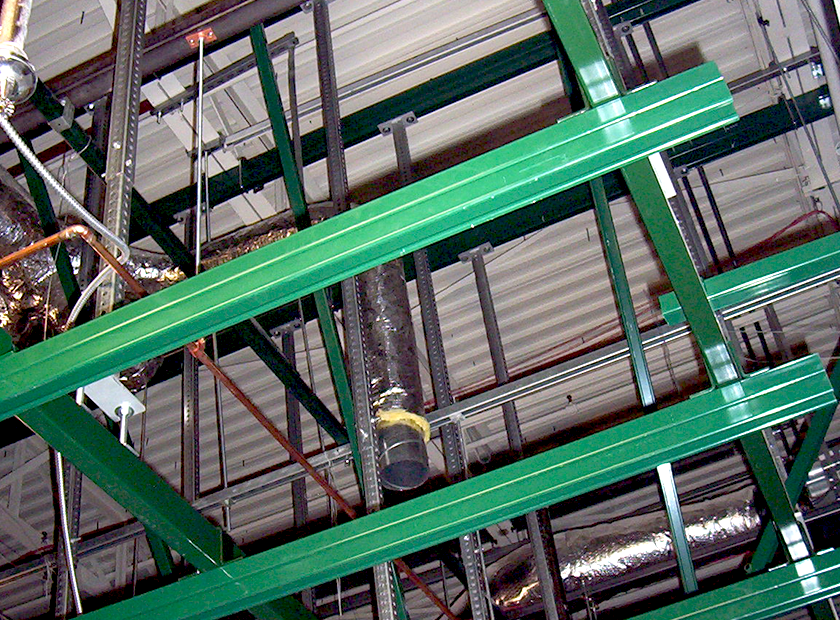

Knowing the right way of mounting Unistrut can be a challenge because there are so many variables to consider. First off, what are you attaching? If your answer to this question is Unistrut grid, then you've found the right blog to help you tackle your project. Now that we know what we are attaching, the next question becomes, what are you attaching it to? The most common scenarios when installing Unistrut grid ceiling are attachment to beams or bar joists, concrete deck, or metal deck.

Knowing the right way of mounting Unistrut can be a challenge because there are so many variables to consider. First off, what are you attaching? If your answer to this question is Unistrut grid, then you've found the right blog to help you tackle your project. Now that we know what we are attaching, the next question becomes, what are you attaching it to? The most common scenarios when installing Unistrut grid ceiling are attachment to beams or bar joists, concrete deck, or metal deck.

Hanging Unistrut doesn't have to be such a great challenge. Below we'll break down just how to hang Unistrut from ceiling for each of the most common Unistrut mounting scenarios.

Method 1: How to Attach Unistrut to a Beam / How to Hang Unistrut from Joist

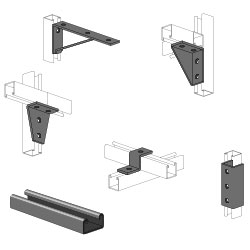

There are an assortment of beam clamps and other attachment fittings, sometimes used in conjunction with threaded rod, which allow for a grid work of Unistrut channel to be attached to your structural ceiling components - in this case steel beam or bar joists. When installed correctly, each approach creates a very strong and safe connection point for a variety of items that need to be securely supported. There are three main appraoches on how to hang Unistrut from joist, or attach to structural beams.

The First Approach: Beam Clamps / Unistrut Hanging Bracket Technique

One way to attach Unistrut grid to joist steel is through the use of Unistrut joist clamps, you might also see them referred to as Unistrut mounting brackets, Unistrut hanging brackets, or even window clamps (such as the P2785, P2786, and P2787). These clamps are manufactured with different u-bolt lengths to acommodate various channel heights and are always used in pairs. When attaching beam clamps to joist, the clamps are attached to the bottom chord of the bar joist. Channel can be attached either above or below the chord.

The Second Approach: Hanging Threaded Rod Unistrut Technique

In this approach, Unistrut channel is attached to the bottom chord of the bar joist - either above or below the chord. The channel and channel nut rests on one side of the chord, while on the other are a flat plate fitting and mounting hardware. The chord is sandwiched between the assembly components and a length of threaded rod runs through everything.

The Third Approach: Joist Wrap Technique

In situations where the bottom chord cannot be attached to, or where the engineer has specified the top chord as the load bearing chord, the joist wrap method is the preferred way to safely and effectively transfer the load that would normally be born by the bottom chord to the top chord, surrounding the joist (or wrapping the joist) in a load bearing Unistrut assembly.

For more detailed information on each of the approaches mentioned above, please scroll down to the end of this blog and check out the related posts section!

For more detailed information about this method, along with drawings and specifications, please click the link directly below.

Method 2: Mounting Unistrut Grid to Concrete Deck

In ceiling Unistru grids are uniquely suited for attachment to your existing concrete deck and supporting everything from lighting, electrical and plumbing, and ceiling tiles, to art work, and even expensive, high-tech medical equipment. In this method, concrete expansion anchors are utilized, along with threaded rod, to suspend your ceiling grid from exisiting concrete deck.

For more detailed information about this method, along with drawings and specifications, please click the link directly below.

Method 3: Mounting Unistrut Grid to Metal Deck

The system for mounting Unistrut grid to metal decking, also known as corrugated metal, is very similar to mounting directly to concrete decking. Expansion anchors are bolted through the decking and threaded rod is used, along with Unistrut fittings and hardware, to suspend your Unistrut ceiling grid.

For more detailed information about this method, along with drawings and specifications, please click the link directly below.

REQUEST A QUOTE TODAY!

DISCLAIMER

STANDARD DETAILS ARE FOR REFERENCE AND DESIGN PURPOSES ONLY, AND ARE NOT INTENDED FOR USE AS FULLY ENGINEERED SYSTEMS. ENGINEERED SYSTEMS MUST TAKE INTO ACCOUNT ACTUAL SITE CONDITIONS (SUCH AS: LOAD, ELEVATION, SIZE, SPACING, BUILDING STRUCTURE, EXISTING MEP STRUCTURES, ETC.) AND BE PURCHASED THROUGH UNISTRUT BUFFALO SUPPORTS, A DIVISION OF EBERL IRON WORKS, INC. 128 SYCAMORE STREET, BUFFALO, NEW YORK 14204. CONTACT UNISTRUT BUFFALO SUPPORTS: 1 (800) 285-3056 UNISTRUTSTORE.COM/REQUEST-QUOTE FOR A CUSTOM QUOTE TAILORED TO YOUR JOBSITE/PROJECT.