- UBS

- 1-5/8" Metal Framing

- 1-1/4" Metal Framing

- Unistrut 13/16" Metal Framing

- Pipe Clamps & Conduit Supports

- Fiberglass Unistrut System

- Food Grade Strut

- Sikla Heavy Duty Metal Framing

- Lindapter Structural Fasteners

- Telespar Mechanical Tubing

- Safety Grating

- Threaded Rod & Couplers

- Unistrut Hardware & Fasteners

- Concrete Anchors

- Dakota Systems Smart Products

Telespar® Square Tubing: Beyond Sign Posts

Telespar Square Tubing Isn't Just For Sign Posts

Telespar Square Tubing Isn't Just For Sign Posts

There are many uses for square steel tubing beyond the traffic safety industry. In fact, when the original makers of Telespar® square tubing (Unistrut Corporation) began manufacturing it, in 1964, there wasn't even a market for square tube to be utilized in sign post applications. Back then, there was no distinction between square steel tubing and mechanical tubing, because there was no such thing as telescoping square tube sign posts yet...

"Its adaptation to traffic control started when the Michigan Department of Transportation asked Unistrut for a better way to support small signposts. It was Herb Henry who collaborated with the DOT to develop the original breakaway system.

Herb traveled from coast to coast, convincing Unistrut distributors that Telespar posts could greatly benefit their municipal customers. Donning a helmet, he’d drive over the signposts to prove their exceptional safety properties. That’s how Herb became a friend of Eberl Iron Works – we were among the first to realize the Telespar system’s potential, and Herb was our longtime Unistrut representative." ~ Remembering Herb Henry, the “Johnny Appleseed” of Telespar signposts

Telespar® square tubing, for both mechanical tubing and sign posts applications, is now manufactured by Allied Tube & Conduit (Both Unistrut and Allied Tube & Conduit are owned by parent company, Atkore International).

Telespar® square tubing, for both mechanical tubing and sign posts applications, is now manufactured by Allied Tube & Conduit (Both Unistrut and Allied Tube & Conduit are owned by parent company, Atkore International).

Due to the fact that nearly all sign post applications occur out doors, sign post applications call for a specific type of square tube. Square steel tubing must be galvanized to protect from weather and prevent rust oxidation. Square tubing must also be pre-punched with round holes on all four sides (or contain perforated knock-out holes: "Qwik-Punch") to accommodate installation hardware and sign mounting hardware.

There is much more to the world of square tube than galvanized, perforated sign posts.

On the one hand, perforated steel tubing uses less material and is therefore lighter weight and less costly. On the other hand solid square tube, without holes, is inherently stronger. Holes weaken the structural integrity of the tubing - which is fine for sign post applications, since it aids in the breakaway system that helps save so many lives in traffic accidents. But for structural applications, you might need a square tube that can handle heavier loads with minimal deflection.

This is exactly why many mechanical applications call for a more robust range of square tubing options. Some jobs require the adjustability of perforated square tubing and fittings, while others will be welded into place and need the added strength of a solid steel tube. Some jobs require a combination of styles for strength and adjustability.

OEM's (Original Equipment Manufacturers) tend to buy a lot more square tube that is solid and unfinished (plain "black" carbon steel, as opposed to pre-galvanized finish). While both the pre-galvanized and carbon steel finishes can be welded (and also painted, hot-dipped or powder coated), ultimately the finish you choose for your project may come down to what you're using it for and where you're using it.

Here's a great example:

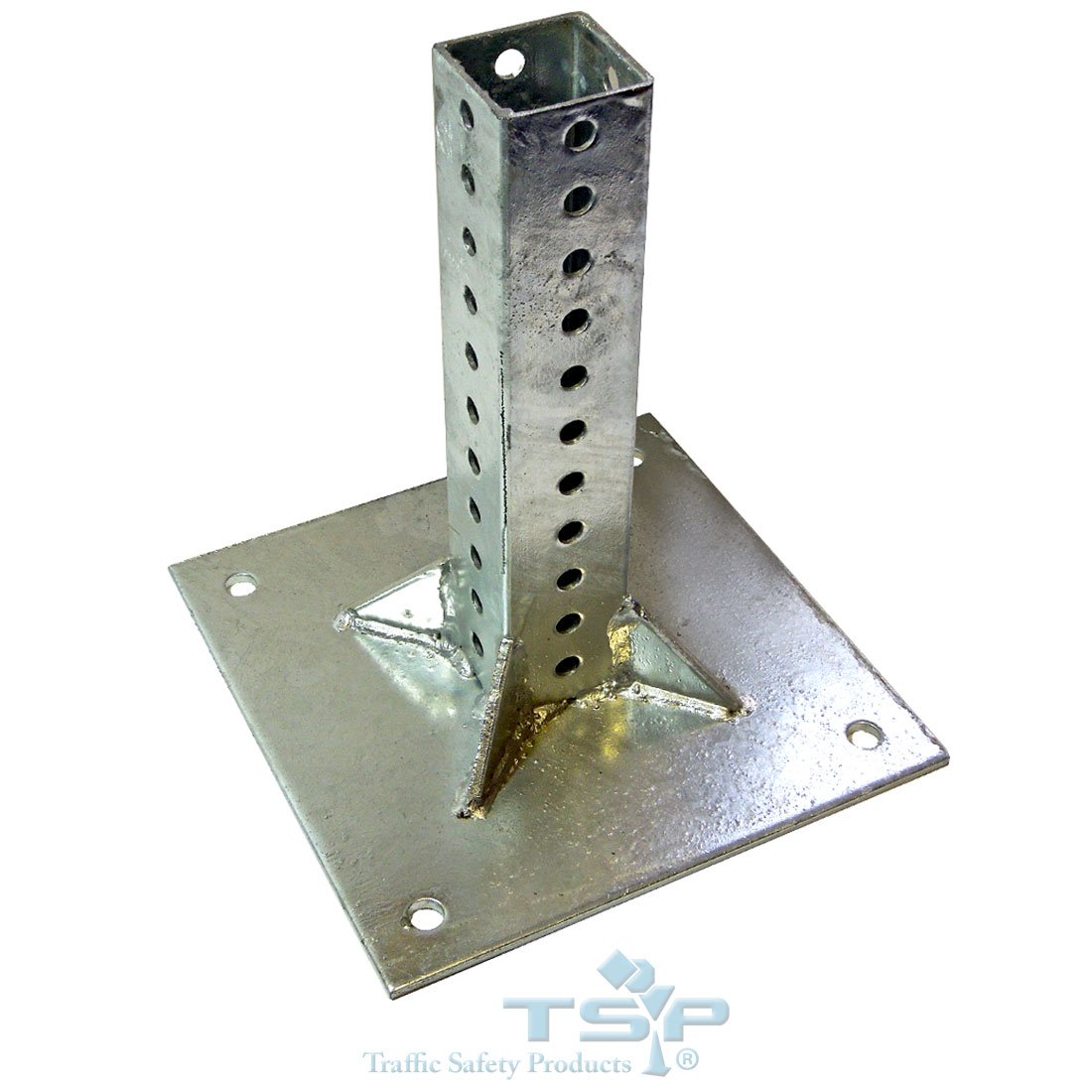

Our Traffic Safety Products division sells a surface mount sign post base that is fabricated by our Metal Fabrication division. We use Telespar square tubing in the manufacture of that base. We weld an upright, receiver section of square steel tubing to a square flat plate, which has been punched with four holes, for mounting. The finish on the tubing is of no consequence to us when we manufacture, so we are able to choose the most cost effective perforated tubing that we stock, because we know that the entire unit will be sent to the galvanizer, for hot-dipping, after it has been fabricated.

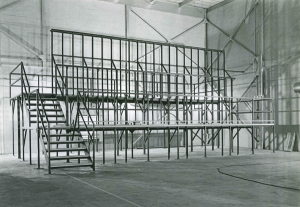

Someone building an indoor framework or mezzanine, where moisture isn't an issue, might opt to build the entire structure out of plain carbon steel tubing and weld the joints together for the greatest amount of structural integrity at the lowest materials cost.

Our customers have used Telespar® for a Wide Variety of Applications:

- Building Ceiling Support Grids

- Equipment Supports

- Railings

- Conveyor Systems

- Equipment Platforms

- & Much More!

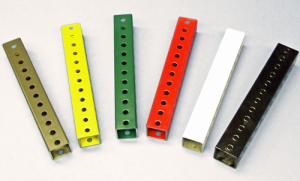

Telespar Square Tubing Specifications

Telespar® tubing is produced through a unique manufacturing process where it is roll formed and in-line corner welded with tight corner radii allowing for smooth telescoping from one size tube to another. Tubing sizes range from 1-1/4” - 2-1/2” on the outside dimension.

The Telespar® system is available in two finishes: pre-galvanized and plain carbon steel. It is available in 10, 12 and 14 gauge material thicknesses.

Hole size is 7/16", 1" on center

Custom Powder Coating options will be quoted upon request