- UBS

- 1-5/8" Metal Framing

- 1-1/4" Metal Framing

- Unistrut 13/16" Metal Framing

- Pipe Clamps & Conduit Supports

- Fiberglass Unistrut System

- Food Grade Strut

- Sikla Heavy Duty Metal Framing

- Lindapter Structural Fasteners

- Telespar Mechanical Tubing

- Safety Grating

- Threaded Rod & Couplers

- Unistrut Hardware & Fasteners

- Concrete Anchors

- Dakota Systems Smart Products

The 'Nuts and Bolts' of the Unistrut Spring Nut

The Spring Nut is a Key Component of the Unistrut Metal Framing System

The spring nut is very often overlooked. When most people think of metal framing systems, they tend to only think about the Unistrut channel and the Unistrut fittings. Despite that fact, Unistrut hardware is an integral part of the core functionality of the Unistrut system – especially spring nuts and channel nuts. So it’s important to know what your options are, when it comes to choosing the right fasteners for the job.

There are two basic categories that channel nuts fall into: channel nuts without springs, and channel nuts with springs, or spring nuts.

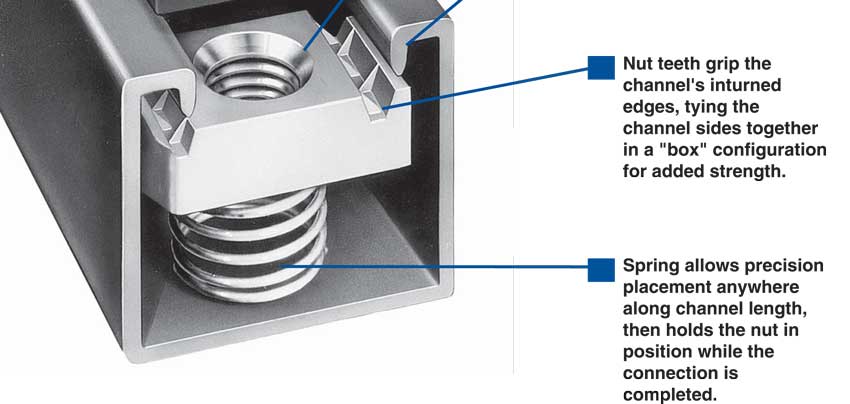

What is a spring nut you ask? Pretty much what it sounds like: it’s a channel nut, with a spring on one side, that slides inside of a piece of strut channel.

The spring takes up the extra space inside the channel, keeping the nut flush against the inturned edges of the channel, so you don't need an extra hand to hold it in place, while you're busy trying to affix parts and tighten them down. The length of the spring helps determine which channel profiles the spring nut can be used in: longer springs for deeper channels and shorter for shallow channel.

Channel nuts, including spring nuts, typically have a threaded hole in the middle which is used to attach fittings to the strut. Unistrut nuts are available with a variety of hole sizes, to accept a range of hex head cap screw (hex bolt) sizes . There are even spring nuts with bolts built in; these are called stud nuts, and they can make the assembly process very quick and efficient.

Channel Nuts and spring nuts also have serrated grooves on one side to help you correctly align them within the channel’s track, and hold them securely in place, during the tightening process and after being tightened.

Picking the best channel nut for your application can decrease your installation time - saving you time and money – conversely, picking the wrong Unistrut nuts can turn a simple job into a laborious process full of headaches.

Imagine you’re on a scaffolding,15 feet in the air, attaching bulky lights to a track of Unistrut channel and you’re using one hand to hold a channel nut in place, inside the strut, while you’re using your other hand to hold the light, and trying to screw the bolt through the light housing, into the channel nut…

Think another hand might come in ‘handy’? And don't drop the channel nut - or the light! That could get expensive, not to mention all of those trips up an down the ladder...

A spring nut, which holds itself in position inside the channel (so you don’t have to), would have made this job significantly less difficult.

However, channel nuts with coiled springs don’t work so well for every application. If you are using a piece of channel that has perforations on the back side (also referred to as slotted channel, or channel with holes), the springs can be difficult to slide within the channel, getting stuck along the way.

Luckily there are some spring nuts with non-traditional springs, like the Top Grip Nut, which has a flexible plastic, tabbed 'collar' to hold the nut in place. Instead of a coiled piece of wire, they are engineered with plastic 'springs' (or collars) that essentially perform the same job as a coiled wire spring, but without interfering with the perforated side of the channel. These type of spring nuts rely on their spring component to 'hug' the inturned edge of the channel, as opposed to pushing against the opposite site of the channel.

Tailoring your choice of channel nut to your specific job application is important - not only for your piece of mind, but to your pocket book!

Tailoring your choice of channel nut to your specific job application is important - not only for your piece of mind, but to your pocket book!

If money is an issue and you're working with a fixed budget, channel nuts without springs tend to be a less expensive option. If you're worried that you might not have enough hands to use springless nuts (you're afraid you'll drop them all in the middle of trying to install them, twenty feet in the air, on a ladder) there are some great options.

Try pre-assembling items before transporting them to your installation site. When you’re standing at a work bench pre-assembling fittings, before bringing them to a job site, a springless channel nut is easy to work with. Even if you have 'butter-fingers' and end up dropping them, they don't have far to fall.

Especially useful for simplifying the process of drop rod installs is the Unistrut Kwik Washer.

The Kwik Washer falls somewhere between a springed and springless channel nut – having properties of both: there is a rigid metal and plastic tab which holds the nut in place, without tying up one of your hands. These can be pre-assembled with threaded rod and slipped into place inside existing ceiling mounted channels with just the twist of a wrist.

Click the button below to shop our entire selection of Unistrut Spring Nuts & Hardware